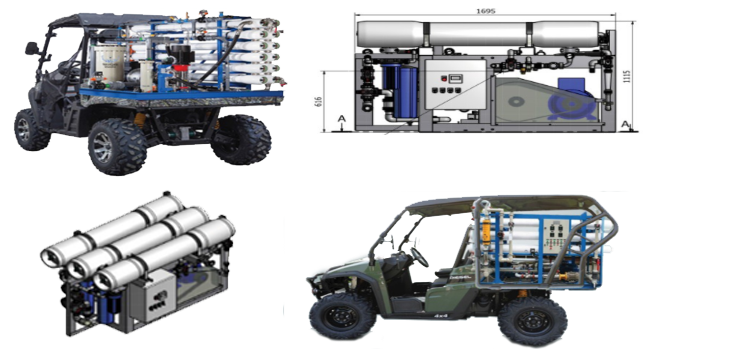

WaterQuest Mobile™ is one of the Innovative decentralized solution to provide fresh drinking water in Coastal areas, areas with poor ground or surface water. The WaterQuest Mobil is configured to produce from 20 M3 to 100 M3/Day of drinking water suitable to treat all types of water sources - Sea water, Brackish water, River water, Lake water, bore well water, highly turbidity water.

About WaterQuest Mobile™

The WaterQuest Mobile™ doesn’t require any external power source as it is powered by the vehicle engine itself and capable of being transported or airlifted to any location in times of emergencies or natural disasters like floods, hurricanes, earthquakes and droughts.

Process Calculations

A combined numerical and experimental approach was used to optimise the module/system design, resulting in ∼20% permeate flux enhancement. Experimental results revealed that the system can produce 16 L per square meter of membrane area per hour (LMH) at a salinity level of 80 ppm from a ∼2000 ppm groundwater when it is feed at 1 m3/h at 8 bars. This indicates that a vehicle equipped with 12 m2 of tubular RO membranes can deliver 1 m3 of drinkable water by using ∼0.9 L of diesel. Assuming eight such systems could be implemented in a community to fulfil the water demands for a village with 2000 residents, a social business study revealed that a payback time of 2.5 years is achievable, even if the sale price of the water is relatively low, Rs 12 per 20 L, which is half of the lowest market price, including providing a goods transportation service at price of Rs 500 per 100 km.

Technology Overview – AI enabled Virtual Prospecting Program

| Source Water Parameters Range | Treated water Parameter Range |

|---|---|

|

|

Vehicle Configuration

| Engine Type | Powerful diesel engine, Minimum 1000 CC |

| Chassis Type | Roll cage Frame supported tubular frame. Completely Knocked down unit. |

| Electric System | CCA Battery capability, Alternator, Horn, Power Socket, Headlights, LED Tail lights, Turn and Brake Lights |

| Instrumentation | Speedometer, Voltmeter, Fuel, Temperature, Low Oil Pressure, Turn Signal, High/low beams |

| Mobility | Good Suspension and powerful engine having an all-terrain Feature |

| Safety | Roll Cage, Compact and less weight for convenient mobilisation (By road and by air) and ease of transportation, Movement option interlock (Unable to move during operation) |

Salient Features

General

- The Water treatment system will be mobile, self-contained independent, automatic operated and mounted on the vehicle.

- The water treatment vehicle can travel to low hilly areas, desert areas, and rocky surfaces.

- The mobile system capable of transported to site by any means of transport.

- The mobile water treatment system integrated with inbuilt energy supply system. No Separate source, external power supply required.

- The system able to perform and produce drinking water at 3000 mtr. above Mean Sea Level.

- The system can be operated – water temp. between 3C to 37C.

- System with Built advance control system, making it very convenient for operation.

- Mobile water treatment has operational capabilities - at 24 X 7 with equal efficiency.

- Capable of Inbuilt diagnostic facility.

- The mobile system has facilities of piping for source water collection and water treatment within the same unit.

- Remineralisation system inbuilt to produce required water.

Advantages and limitation

- The mobile system is compact and less weight for convenient mobilization.

- The size of the mobile treatment vehicle will be easy for transportation.

- The system will be plug and play type and easy to operate.

- Vehicle cannot move during the purification process.

Safety

- 12V low voltage system or suitable power inbuilt voltage system.

- A rolling cage – cabin.

- Movement operation interlock - unable movement during operation.

Project Timelines

Approximate timelines post signing of the WaterQuest Mobile™ supply contract:

| Source Water Parameters Range | Timelines (Days) |

|---|---|

| Contract Signing wth Advance | T |

| Procurement | T+60 days (60) |

| Assemble | T+85 days (25) |

| Testing Water Sample Report and Hand over | T+100 days (15) |

| Total | 100 |

Operation Troubleshooting and Maintenance Procedure

Operation and Maintenance includes mainly two units of the system

Vehicle

As general this vehicle needs periodic servicing oiling and greasing. Vehicle comes with 1 year limited and 2 year battery warranty.

Desalination Unit

Periodic replacement of membranes and filters are required as per TDS value of source water for efficient desalination procedure.